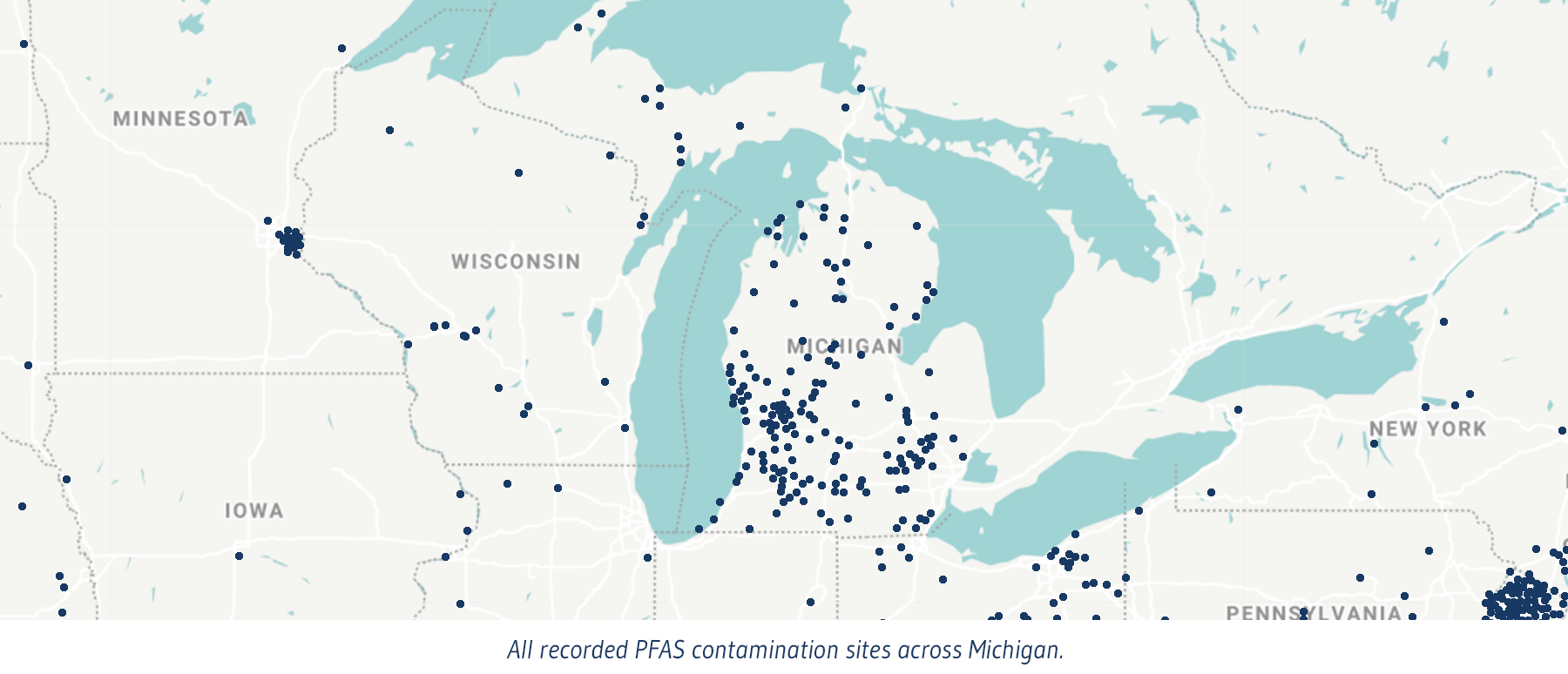

The state of Michigan is setting some of the nation’s toughest standards for measuring and controlling the widely used set of PFAS chemicals that do not break down readily in the environment and bio-accumulate within an ecosystem. G2 Consulting Group has become a leading national PFAS investigator conducting dozens of projects in Michigan and other states.

Michigan’s fight against these pervasive and persistent “forever chemicals” requires PFAS identification and remediation at levels in the parts per trillion. Consider that one part per trillion is equivalent to a single drop of water in 20 Olympic-sized swimming pools, or one drop of water in 660 rail tank cars (that would be a train six miles long!), which begins to define the complexity of accurate PFAS investigations.

When looking for trace materials, the key, according to G2 Consulting Project Manager Thomas McDonald, is absolute vigilance in testing protocols.

“As experts in environmental consulting and geotechnical engineering services, G2 understands the enormous sensitivity required for accurate PFAS results,” says McDonald. “PFAS chemicals can affect the health of individuals or even entire communities. Therefore, we’ve developed a comprehensive checklist of PFAS investigation do’s and don’ts to ensure our clients understand their potential exposure and liability,” he said.

PFAS (per- and polyfluoroalkyl substances) is a group of man-made chemicals that includes PFOA, PFOS, GenX, and many other chemicals that have been manufactured and used in a wide variety of industries since the 1940’s. Because of this, PFAS was omnipresent in household and industrial items prior to 2015, including in chemicals associated with manufacturing facilities, paper mills, landfills, wastewater treatment plants, military bases, electroplating plants, aerospace industry, tanneries, Teflon related facilities, and numerous other innocuous properties.

Therefore, G2’s PFAS protocol checklist includes the following recommendations:

Field staff

- No Gore-Tex products

- No cloths laundered with fabric softeners

- No unauthorized cosmetics, moisturizers, hand creams, or sunscreen

- No waterproof or resistant rain gear

- Field staff should wear safety boots made from PVC and polyurethane

Field equipment

- No Teflon or LDPE materials

- No waterproof books on-site

- No plastic clipboards, binder, or spiral notebooks.

- All sample materials made from stainless steel, HDPE, acetate, silicon, or polypropylene.

- These are just a handful of the many PFAS investigation best practices that G2 employs for its clients.

Experts have only recently begun to understand the prevalence of PFAS as well as the potential adverse health effects of exposure. G2’s expertise is helping clients understand their potential exposure and offering solutions in instances where PFAS is present. The recognition and proper evaluation of a property for the presence of PFAS is a critical part of any environmental due diligence process.